Thank you!

Our employee will process your data and will contact you shortly.

We value each of our clients and are always glad to see you

on our website.

TOMOGRAPHIC UD4-TM (2.69)

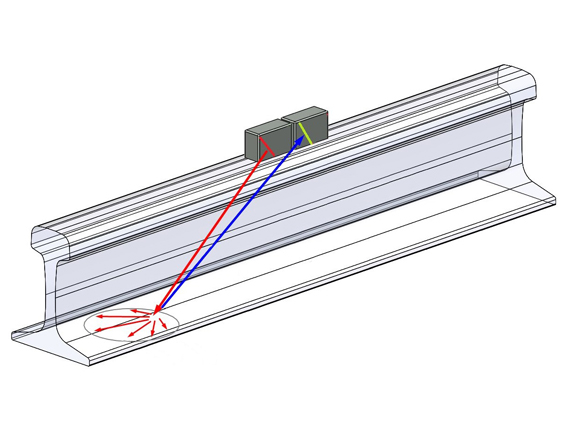

The universal flaw detector TOMOGRAPHIC UD4-ТМ (v.2.69) has a built-in function for determining the coordinates of defects, conditional sizes and the detection coefficient, and also ability to conduct refining inspections with manual searchers. Production, technical and operational defects in the form of discontinuities with a height and length of 6 mm or more are subject to detection. The main purpose of the flaw detector is to detect defects in the rail base blades by ultrasonic flaw detection, the principle of transformation of ultrasonic waves (Ultrasonic control) is shown in Fig.2.

Flaw datavisualization

_.jpg)

___.jpg)

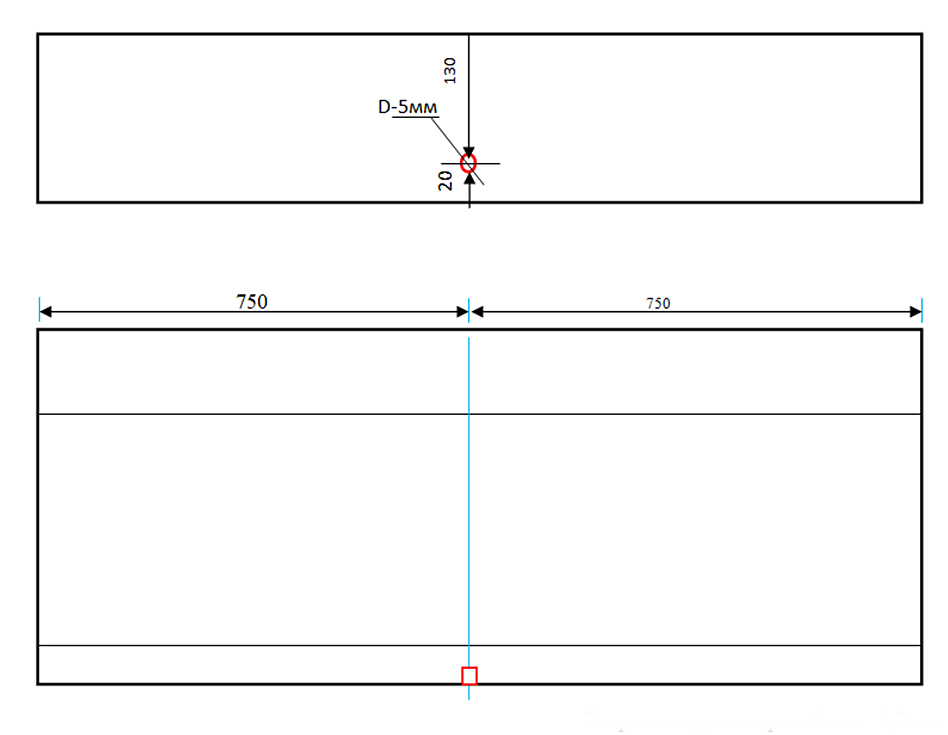

Configuration of the main channels of a flaw detector is carried out at a check spur track rail with an artificial defect in the form of a drilled holewith a diameter of 5 mm in pen soles rail. Manual scanners are to be calibrated on SO-3P.

Fig. 1 Scheme of an artificial defect locatedin the rail base

Drilled hole with a diameter of 5 mm + 0.2 mm

Fig. 2 Ultrasonic waves transformation principle

The dead zone is 350 mm (the distance between the scanning beam drive point and the bottom of the rail at an angle of 50°).

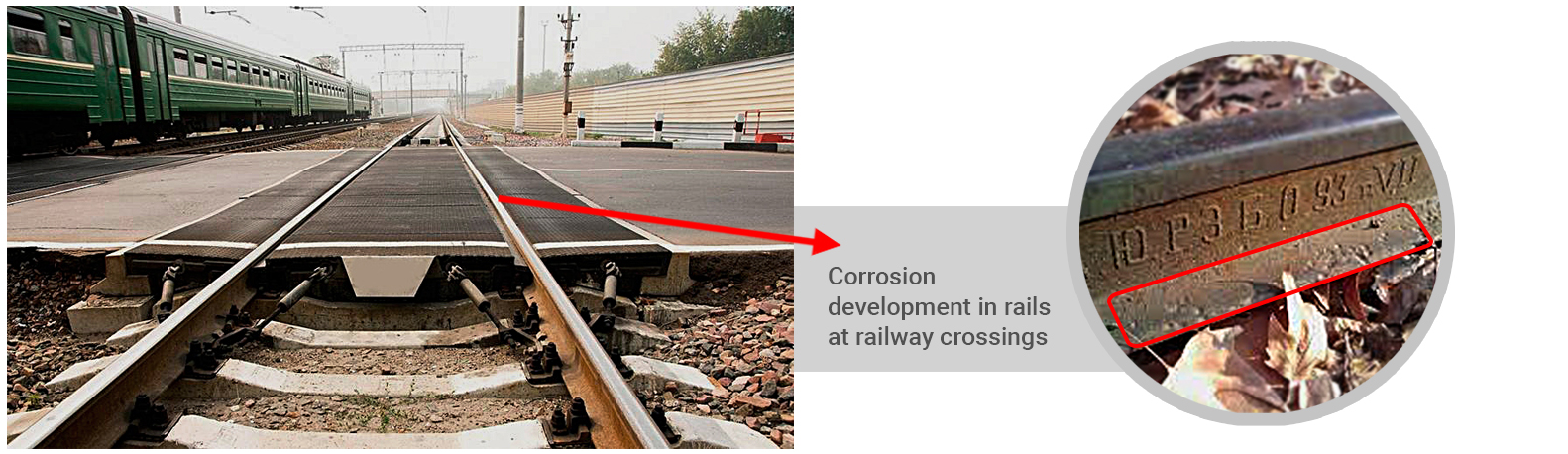

Flg 3. Actual confirmation of the defect by mechanical destruction

The universal flaw detector TOMOGRAPHIC UD4-ТМ (2.69) is an effective means for rail control at level crossings, because they most at corrosive risk.

Scope of delivery: