Thank you!

Our employee will process your data and will contact you shortly.

We value each of our clients and are always glad to see you

on our website.

KALMAR 32+

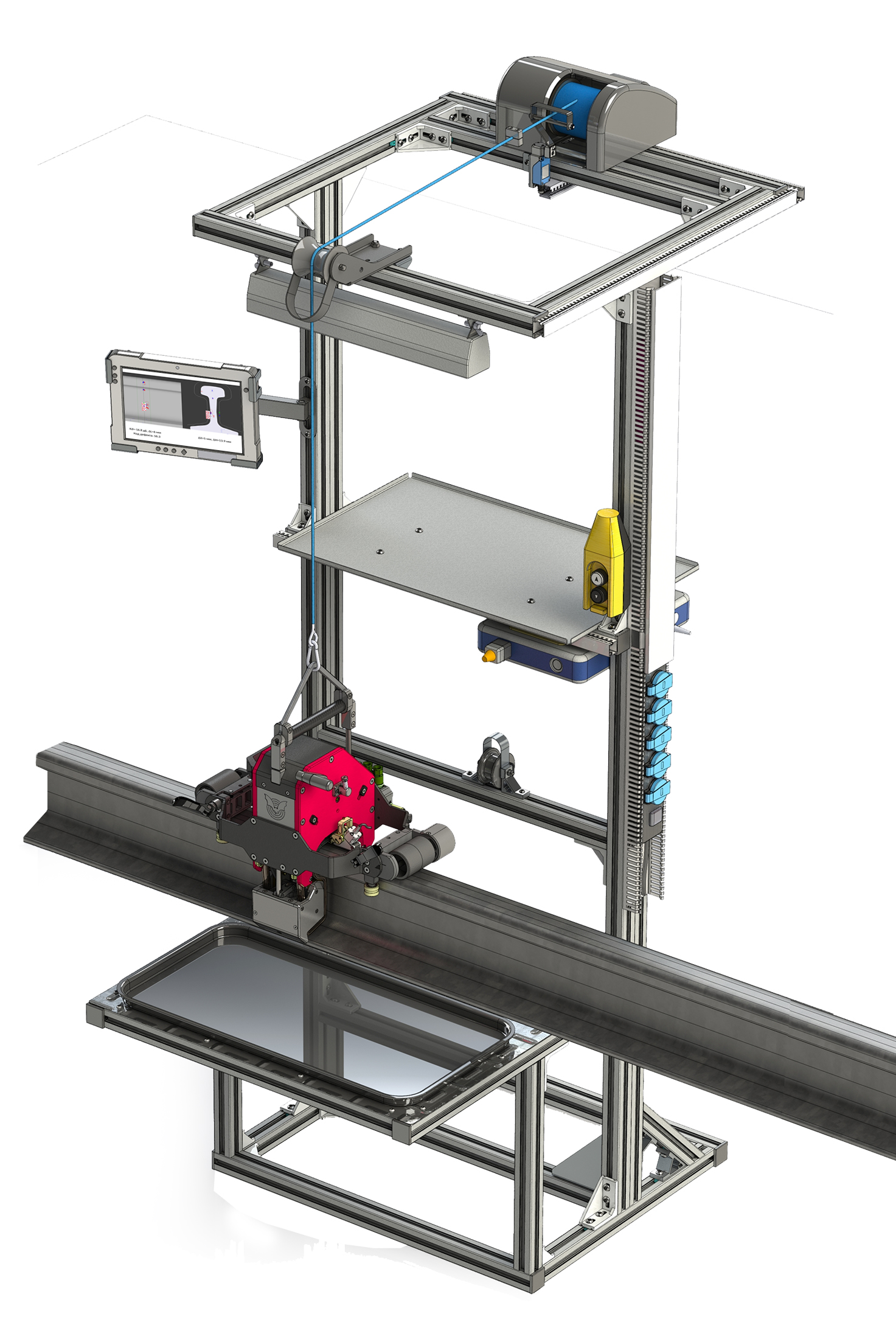

Ultrasonic flaw detector on phased arrays for monitoring aluminothermic and electrocontact welded joints of rails - KALMAR 32+, is: a mechanical scanner with pre-installed probes on phased arrays, a flaw detection unit and a control PC tablet. All control functions are performed by the operator. There are two versions: stationary for use in rail welding enterprises (see Picture 2) and mobile - moved along the railway thread of the rail (see Picture 1).

The scanner is installed in the center of the weld. With the help of a mechanized drive, the converters on the FR move along the forming weld along the entire section of the rail (head, neck and feathers of the sole). The software of the flaw detector includes standard settings for the control of welded joints: aluminothermic, electrocontact and gas-pressure. The average inspection time of one welded joint is 5 minutes.

Pic 1. KALMAR 32+/ PATH Pic 2. KALMAR 32+/ RSP

In real time, a "B" scan is formed on the screen of the flaw detector in the form of a rail contour with defect parameters: coordinates, location in the section of the weld, conditional dimensions, detection coefficient. A detailed analysis of all signals is available in the "A" and "S" scans.

Features and advantages of КАLМАR 32+:

• Determination of the converter parameters using the standard sample SO-3R;

• Semi-automatic adjustment to conditional sensitivity according to SO-3R;

• The presence of the acoustic contact tracking function;

• Storing the control results in the database in the form of a protocol, including the display of diagnostic parameters (sensitivity, examination time, conditional dimensions of defects, detection coefficient);

• "Auto-size" and "auto-protocol" functions;

• Alarm about the presence of defects – sound and color on the monitor of the flaw detector.