Thank you!

Our employee will process your data and will contact you shortly.

We value each of our clients and are always glad to see you

on our website.

BLENDING SCOPE WIZARD

Wizard Blendoscopes range comprises essential units and modules designed for the diagnostics and maintenance of engine parts and gas turbine units blades

Wizard Blendoscopes are designed for:

removel of nicks, burrs and/or notches in hard-to-reach places of products;

flaw detection using capillary and eddy-current method of control;

visual measurement control involving the installation of dimensional templates and subsequent inspection

Testing techniques:

Wizard Blendoscope kits include time-tested, in-house-produced systems.

The completeness of the borescope system is determined by the customer

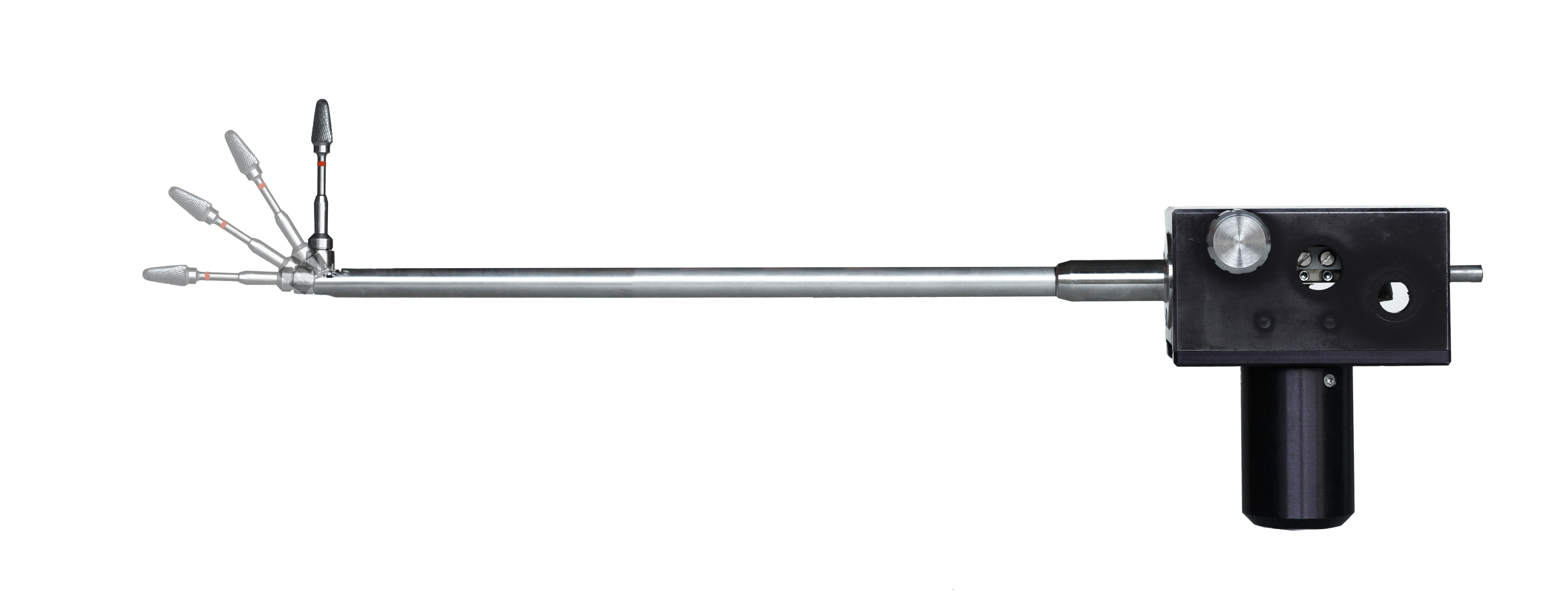

The basis of the blendoscope is a long canulla with an instrument at the end and with a built-in technical endoscope (borescope).

The head at the end of the tube is tiltable. When inserting and removing the blendoscope, the heard straighten with the tool

Wide range of models of varios diameter and lenght provides solutions for most tasks:

WIZARD 8.22, tube Ø 8 mm L= 22 cm

WIZARD 8.46, tube Ø 8 mm L= 46 cm

WIZARD 6.46, tube Ø 6 mm L= 46 cm

Сlear visibility of hard-to-reach places during work

Ability to display image on a monitor

FEATURES:

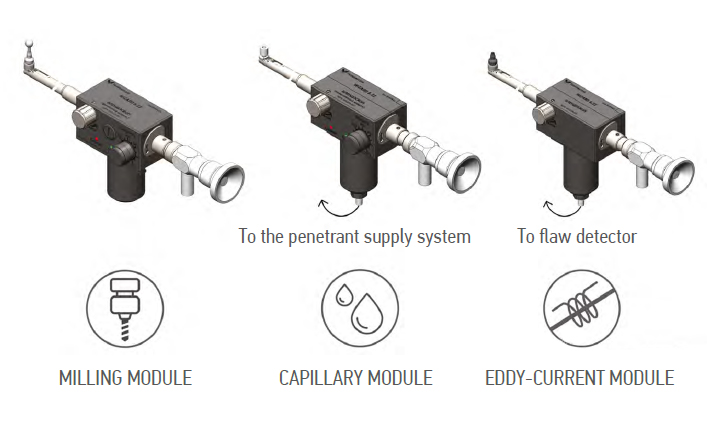

The blendoscope is avialable in the following versions:

MILLING MODULE

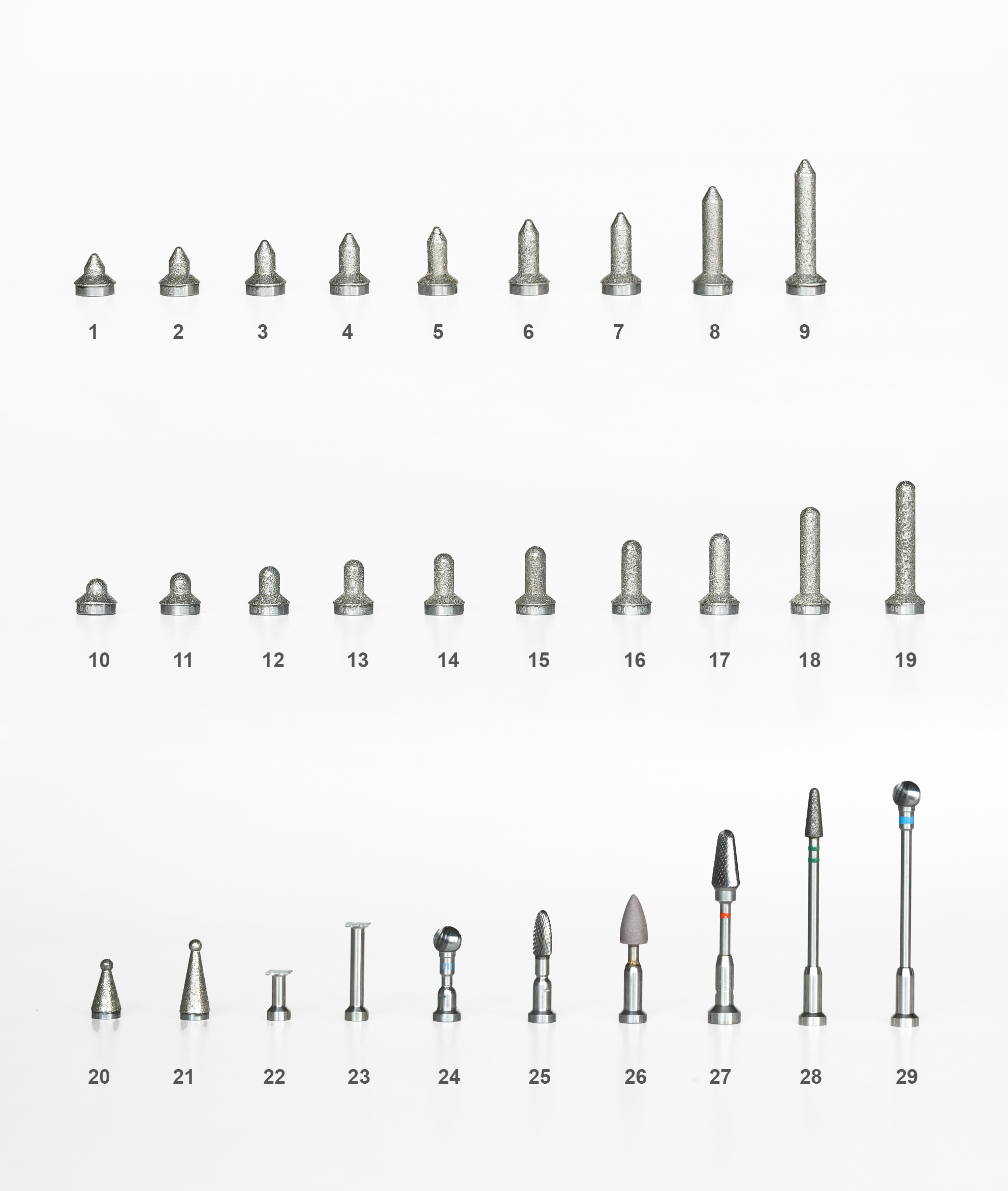

This module is designed for the detection and mechanical processing of dents, burrs and/or serrations in hard-to-reach areas of parts, as well as complex-shaped assemblies, such as turbine engine blades or others. It also incorporates functions for visual-measuring control

Applied for:

mechanical processing of dents, burrs and/or serrations;

measurement of dimensions (cracks, serrations, etc.) using dimensional templates;

detection of foreign objects whithin enclosed structures

detection of areas where changes in material structure lead to alterations in the optical properties of the surface (color, brightness, gloss)

CAPILLAR MODULE

Intended for conduction brightness, color, fluorescent and fluorescent-color inspection using penetrating (penetrant) substances,

according to established regulations and standards

Applied for:

detection of various surface defects on parts and assemblies of aviation equipment at various stages of aircrafts, helicopter and engine manufacturing, during technical inspections as well as during maintenance;

identification of surface defects: cracks and dents of assemblies that are accessible for direct inspection or in hard-to-reach areas;

detection of finer cracks (compared to those detectable without special substances) during color and fluorescent inspections;

analysis of the nature and determination of the type of surface defects

EDDY-CURRENT MODULE

Intended for conduction non-destructive testing using the eddy-current method of aviation engines and industrial turbine equipment,

covering a frequency range from 5 MHz, depending on the material being tested

Applied for:

detection various types of surface defects on components and assemblies of aviation equipment at different stages of aircraft, helicopter and engine production, as well as during technical inspections and maintenance;

identification of surface flaws including assemblies cracks assemblie to direct inspection or in hard-to-reach areas

Milling / Capillary module

Working position 80°-100°

Milling tool