Thank you!

Our employee will process your data and will contact you shortly.

We value each of our clients and are always glad to see you

on our website.

DAMI-C09

TESTING METHODS AND PROBES (PDF)

MULTI-FUNCTIONAL FLAW DETECTOR DAMI-С09:

Destination and application field:

Multi-functional flaw detector DAMI-С09 is a small-size, portable instrument intended for manual and automated nondestructive testing under MIA, eddy-current and impact methods.

DAMI-С09 can be used in shipbuilding, aerospace and motor vehicle industries, civil engineering and other branches of industry for testing articles both in the process of manufacturing and in operation conditions.

FUNCTIONAL FEATURES OF DAMI FLAW DETECTOR

DAMI-С09 operation in the mode of MIA testing:

DAMI-С09 operation in the mode of MIA testing:

It implements MIA methods of flaw detection based on changes in the generation mode of mechanical oscillations in the transducer bar contacting with surface of the tested object recorded with changes of mechanical impedance of the tested area;

It is designed for diagnostics of units and body parts of solid composite materials or honeycomb structures in order to reveal laminations and defects of the lack-of-adhesion type.

Operation principle

Voltage of the driving pulse generator (DPG) is supplied on the piezoelectric element of the MIA probe resulting in mechanical oscillations excited in the MIA transducer (MIAT) bar connected by point contact with tested object. In the presence of flaws located closely to surface, mode of oscillations in the bar changes resulting in variation of signal induced in the MIAT measuring piezoelectric element. Signal received from the MIAT measuring piezoelectric element is analyzed by amplitude-phase method. When the given activation threshold (set by strobe) is exceeded, signal of the automatic flaw alarm (monitor signal) is generated. Processing result of signal received from the tested object is displayed graphically on the instrument screen and/or is stored in the instrument nonvolatile memory.

DAMI-С09 operation in the mode of eddy-current testing:

DAMI-С09 operation in the mode of eddy-current testing:

It implements methods of eddy-current flaw detection based on registration of changes of electromagnetic field of eddy currents induced by exciting coil in the conductive tested object;

It is intended for nondestructive testing of parts of nonmagnetic materials and ferromagnetic metals and alloys in order to reveal surface flaws like cracks, laminations, rolling laps, cavities, nonmetallic inclusions, as well as to evaluate structure of the tested material.

Operation principle

Voltage of the driving pulse generator (DPG) is supplied on the exciting coil of eddy-current probe (ECP) resulting in eddy currents excited in tested material. In the presence of flaws located closely to surface, the path of eddy currents changes resulting in variation of signal induced in the ECP measuring coils. Signal received from ECP measuring coils is analyzed by amplitude-phase method. When the given activation threshold (set by strobe) is exceeded, signal of the automatic flaw alarm (monitor signal) is generated. Processing result of signal received from the tested object is displayed graphically on the instrument screen and/or is stored in the instrument nonvolatile memory.

DAMI-С09 operation in the mode of impact testing:

DAMI-С09 operation in the mode of impact testing:

It implements methods of impact flaw detection based on the rebound time of probe striker performing the rated impacts on the tested object surface recorded with change of mechanical impedance of the tested area;

It is designed for diagnostics of units and body parts of solid composite materials or honeycomb structures in order to reveal laminations and defects of the lack-of-adhesion type.

DAMI-C09 in water and ice search mode in cellular structures:

DAMI-C09 in water and ice search mode in cellular structures:

Implements an indicator method for determining moisture and possible classification options – "ice"/ "water" using a PADI probe. Determines the area of the spot and quantitative indicators of moisture using an electric capacity sensor EMK. The operation of both sensors is based on dry-point contact with the object of control, so measurements are effective in any climatic period of aircraft operation. Contact with the surface of the object of control is carried out in any position of the probes.

Operation principle

Voltage of the driving pulse generator (DPG) is supplied on the electric magnet of impact probe (IP). As a result, probe striker with receiving piezoelectric element and alumina protector at its end performs the rated impact on tested surface with voltage pulse occurring in the receiving piezoelectric element. In the presence of flaws located closely to surface, shape of voltage pulse in the receiving piezoelectric element changes. Signal received from the IP receiving piezoelectric element is analyzed. When the given activation threshold (set by strobe) is exceeded, signal of the automatic flaw alarm (monitor signal) is generated. Processing result of signal received from the tested object is displayed graphically on the instrument screen and/or is stored in the instrument nonvolatile memory.

SPECIALIZED TESTING EQUIPMENT AND TECHNIQUES

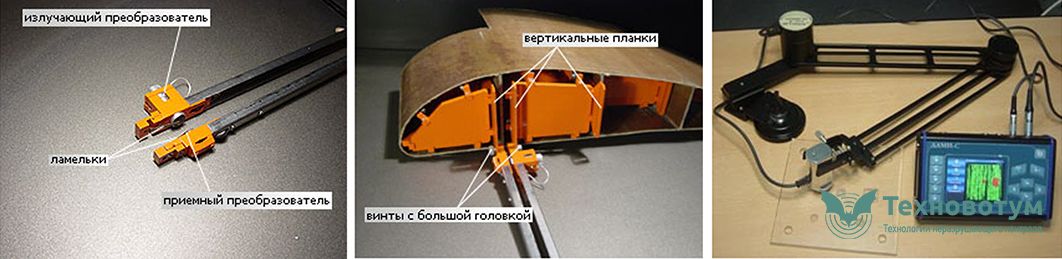

Within the frames of collaboration with the number of aircraft manufacturing facilities, an original technique was elaborated for testing of internal walls of assembly made of 4-layer plastic of fiber-glass fabric (FGF) of 2.7-3.0 mm thickness of pack for defects of the lack-of-adhesion. For testing, through-transmission velocimetric method is used with special probes designed for it.